Scanna launches new product line for Industrial Non-Destructive Testing

Scanna (1) have launched their latest x-ray product family for the Industrial Non-Destructive testing (NDT) market. NDT is the process for testing the quality of products, equipment and components without destroying them (2). According to Fortune Business Insights, the global NDT market size is projected to reach USD 16.66 Billion by 2029, at CAGR of 13.66% during forecast period 2022-2029 (3).

Scanna has been designing and manufacturing portable x-ray systems and detection equipment for the Defense and Security sectors for over 30 years, now Scanna are bringing their quality, reliability and expertise to the world of NDT.

Scanna has designed a comprehensive range of ruggedized, portable digital radiography (DR) systems for NDT applications. By working closely with their customers, Scanna offer tailored solutions to meet specific challenges.

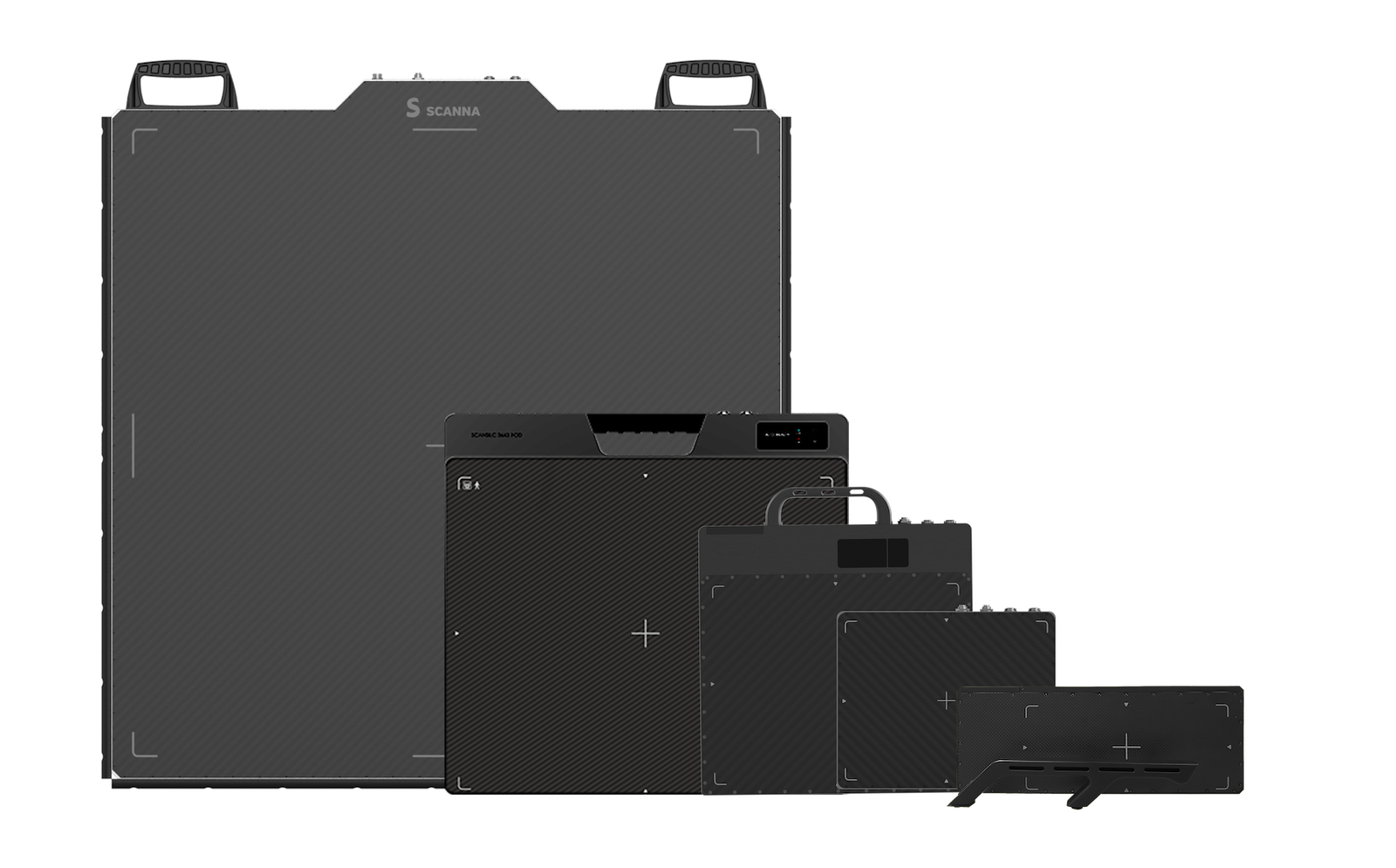

Scansilc NDT x-ray systems are a packaged solution including a panel, generator, tablet/PC and software. Ideal for Mobile NDT applications such as pipe weld inspection, inspecting and decommissioning munitions. For customers with their own generators Scanna can offer panel-only solutions in a range of sizes from 97 x 233 mm to 860 x 860 mm (active area).

The integrated design of the Scansilc panels means fewer components and enables Scanna to offer smaller, lighter “on target” systems than other ruggedized portable X-ray units available on the market. Scansilc NDT Imagers have near edge-to-edge imaging, and are impact and drop tested. These unique IP67 rated panels are designed for use in all weather conditions and provide protection from dust, mud, rain and even snow without any additional protective cover.

Scansilc NDT x-ray systems offer a best-in-class combination of high image quality and rugged field performance. They are designed to deliver reliable results very quickly, and can operate up to a full day on battery power alone. Scansilc panels are highly sensitive which means they can operate on lower x-ray exposure times without any loss of detail. The slim form factor of the Scansilc Panels makes them suitable for sliding into tight gaps and can operate via cable or wire-free to allow for fast place and fire operation and full flexibility of movement.

Without compromising reliability, Scanna's portable, high-performance, DR x-ray systems offer durability and robustness which ensures image quality even in the most challenging environments.

Providing portable DR x-ray systems for NDT, Scanna are enabling their customers to keep their assets safe using preventative maintenance and assuring quality in manufacturing, production and in the field.

Noel Cummings, CEO of Scanna commented “Our vision at Scanna is to utilize our world leading x-ray technology to develop quality assurance systems that keep the world safe”.

For more information contact:

Tel: +44 (0)20 7355 3555 (EMEA) +1 941 925 9730 (USA)

Email: info@scanna-msc.com

For more information about Scanna-MSC and its products visit https://www.scanna-msc.com/uk

About Scanna-MSC

Scanna-MSC has been manufacturing portable x-ray systems and detection equipment for the defense and security sectors for over 30 years. With operations in the UK and USA, we offer on-site training and support wherever our clients have a presence around the globe. Our products are frequently used in high threat situations including Counter EO, protecting the public, government and private organisations and individuals, so our ethos of “without compromise” underpins everything we do – from design and manufacture, through to installation, training and support.

Scanna x-ray equipment is trusted in more than 100 countries and is used Military Organisations, Police and Specialist Agencies, Transport Providers, Borders and Customs, Embassies, Prison Facilities plus a wide range of Commercial Organisations, Educational Facilities and Private Individuals. We also work with National Governments to support Major Events and Safer Cities Projects.

What is non-destructive testing?

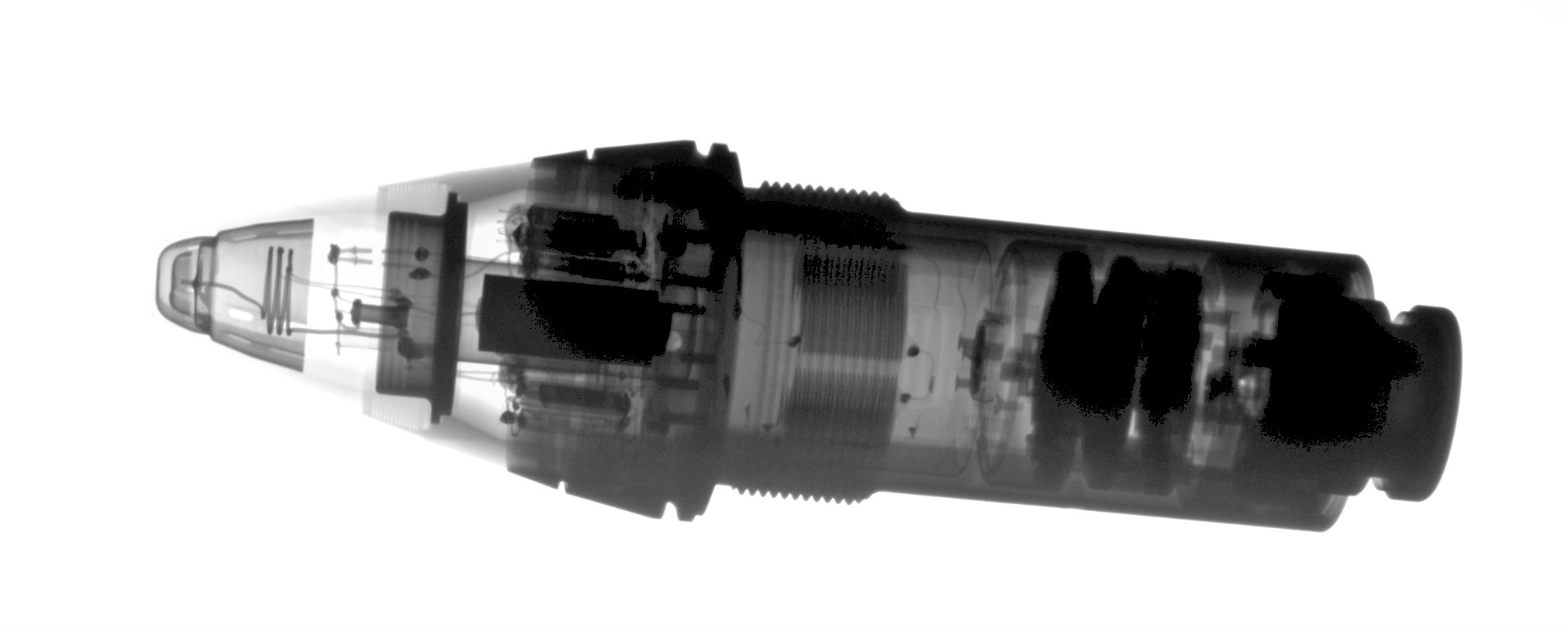

Non-destructive testing (NDT) (also known as non-destructive Inspection (NDI) and non-destructive Evaluation (NDE) is a process by which manufacturers look to detect, measure and analyse for hidden faults and flaws. This inspection process aims to test products without destroying them. Using X-ray in NDT manufacturers are able to look for contaminants, defects, cracks and misaligned parts and are able to test and inspect connecting elements such as large metal castings, welded joints and assemblies without damaging or breaking the part being inspected.

As manufacturing has developed in scale so has the focus on safety and product quality. For manufacturers in automotive and aerospace industries – ensuring the safety and validity of components is paramount. Failures in the field can be associated with enormous financial costs and damage to a manufacturer’s reputation. To prevent such problems arising quality standards have become increasingly demanding calling for 100% inspection of all parts.